[wplp_clear /]

This pad printing system consists of two G2-150 based printers, outfitted with tooling and related accessories, for the purpose of printing military ordnance casings, which are cylindrical in shape.

The first printer, features a standard G2-150 with 150mm inking kit, a servo-driven part transport system and automatic pad tape-off unit. This printer is used to mark the bottom of the part, and is hand loaded and unloaded by the operator.

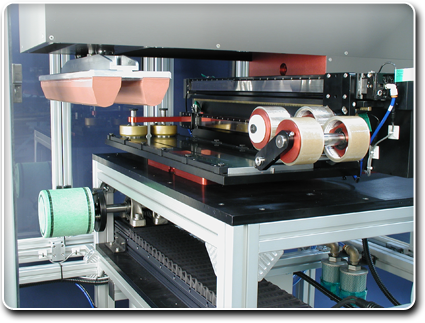

The second pad printing system, shown in close-up at right, consists of a G2-150 print head with a dual 60mm transverse inking kit and matching dual bar pads. The fixture tooling for the ordnance casing is a servo-driven rotating fixture, which works in tandem with the bar pads to allow two stripes to be printed 360 degrees around the circumference of the part. Both printers feature automated printing pad tape-off units.

Both machines perform all printing and indexing functions automatically; the operator is only required to load and unload casing.