Sigma Inks Are Backed With The Following Certifications:

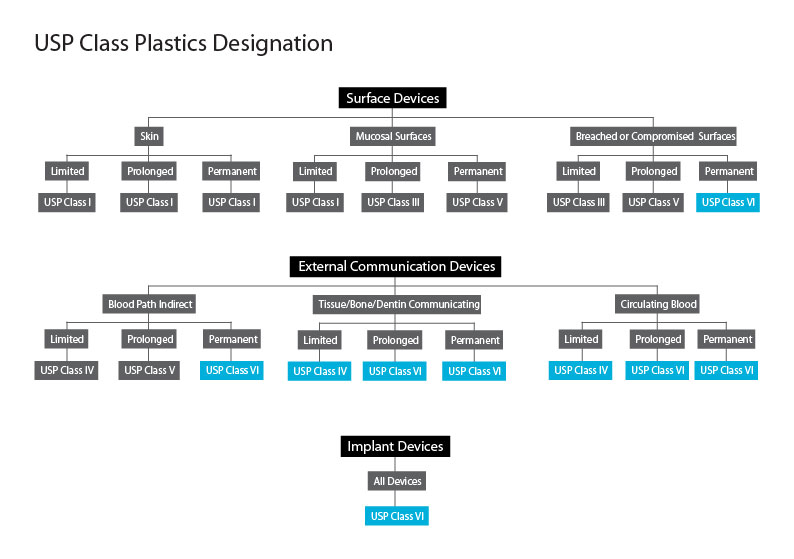

USP Class VI Medical

The United States Pharmacopeia (USP) is an independent organisation that established a set of standards to ensure the quality of medicines and health care technologies. USP protocols are used to classify material in Classes I – VI, based on end use, type and time of exposure of human tissue, of which Class VI requires the most stringent testing of all the six classes.

Printex is proud to announce the addition of 3 more Sigma Series Inks that have just passed the required Biolgical Reactivity Test for USP Class VI:

UV Series (UV-Curable) (Full report)

UR Series (Urethane Base) (Full report)

PP Series (Untreated Poly-Pro) (Full report)

Join the already popular MP Series (Multi-Purpose) ink rounding out a complete medical grade arsenal available for any medical application.

REACH

What is REACH?

REACH is a European Union regulation concerning the Registration, Evaluation, Authorization and restriction of Chemicals. It came into force on 1st June 2007 and replaced a number of European Directives and Regulations with a single system.

The list of restricted chemicals is updated regularly, be sure to keep up-to-date on the current list.

RoHS

What is RoHS?

RoHS stands for Restriction of Hazardous Substances. RoHS, also known as Directive 2002/95/EC, originated in the European Union and restricts the use of specific hazardous materials found in electrical and electronic products. All applicable products in the EU market after July 1, 2006 must pass RoHS compliance.

What are the restricted materials mandated under RoHS?

The substances banned under RoHS are lead (Pb), mercury (Hg), cadmium (Cd), hexavalent chromium (CrVI), polybrominated biphenyls (PBB), polybrominated diphenyl ethers (PBDE), and four different phthalates (DEHP, BBP, BBP, DIBP).

MIL-SPEC

What is MIL-SPEC A-A-208B Type I & II?

The performance based ink specification is prefaced by the description:

COMMERCIAL ITEM DESCRIPTION

INK MARKING, STENCIL, OPAQUE

(POROUS AND NON-POROUS SURFACES)

The performance test catagories include:

- Drying Opacity (Hiding Power)

- Color according to ASTM D 1729

- Gloss

- Stenciling

- Resistance to Rubbing

- Resistance to Water

ISO 9001:2015

What is ISO 9001:2015?

This standard is based on a number of quality management principles including a strong customer focus, the motivation and implication of top management, the process approach and continual improvement. Using ISO 9001:2015 helps ensure that customers get consistent, good quality products and services, which in turn brings many business benefits.

ISO 14001:2015

What is ISO 14001:2015?

ISO 14001:2015 specifies the requirements for an environmental management system that an organization can use to enhance its environmental performance. ISO 14001:2015 is intended for use by an organization seeking to manage its environmental responsibilities in a systematic manner that contributes to the environmental pillar of sustainability.

ISO 14001:2015 helps an organization achieve the intended outcomes of its environmental management system, which provide value for the environment, the organization itself and interested parties. Consistent with the organization’s environmental policy, the intended outcomes of an environmental management system include:

- enhancement of environmental performance

- fulfillment of compliance obligations

- achievement of environmental objectives