Tooling to support the versatility of your Investment:

Chances are that you did not by your Printex Modular pad printing machine with Embedded Plug and Play features just to do one job… This is how we can help your printer grow into the future.

Custom Tooling Videos

Medical Device 3 position 30ml CSTD Printing System

Base Machine: G8-150 DAW

- Printex model G8-150 DAW pad printer with automatic pad cleaning tape-off unit.

- Independently actuated print heads

- Mitsubishi PLC and HMI for seamless control and monitoring.

- Quick Change Pad Feature

- Quick change, zero adjust Inking cup drive system.

- Quick-change part-holding fixture with fully programmable rotation and linear positioning, ensuring precise placements during the printing process.

- Guarding with interlocked safety switch doors and Keyence light curtains enhances operational safety.

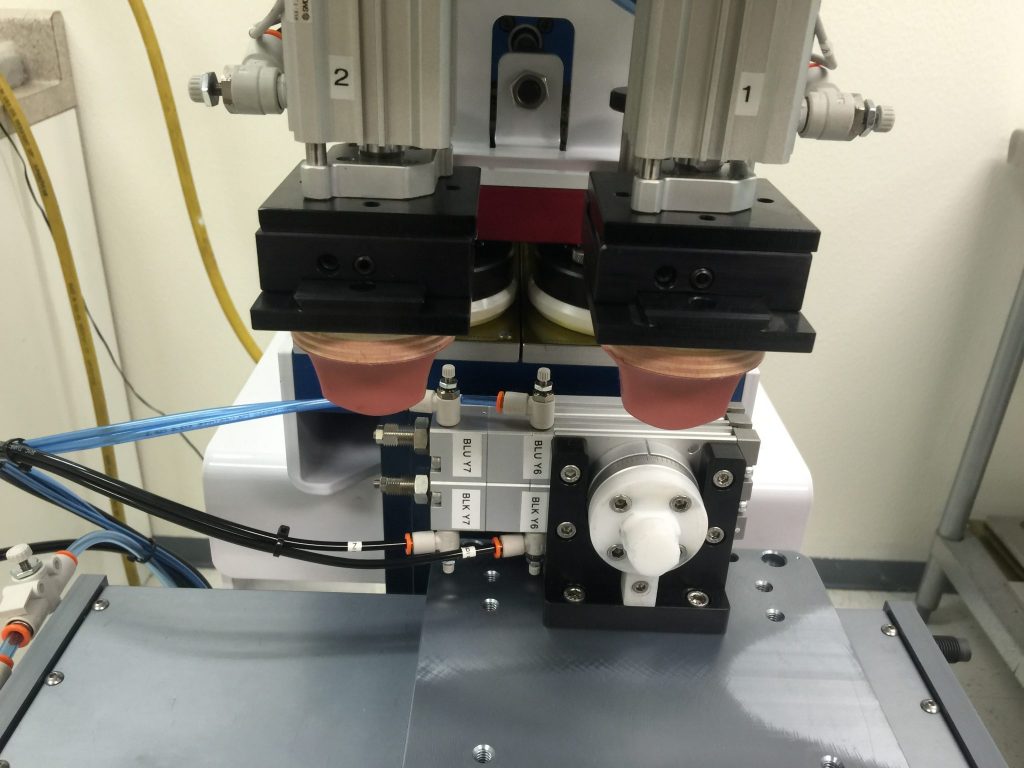

Medical Catheter, (2-up) 360° Printing system

- Two catheters, 360°printing, maximum length up to 30 inches

- Tape cleaning device

- Revolutionary, patented, articulating printing heads

with single-angle silicone print pad’s printing 360° images - Specialized 2 up catheter part-holding fixture

- Allen Bradly PLC and HMI w pre-programmed job settings

- Servo-controlled Ink, Fixture and Printing Head Drive systems

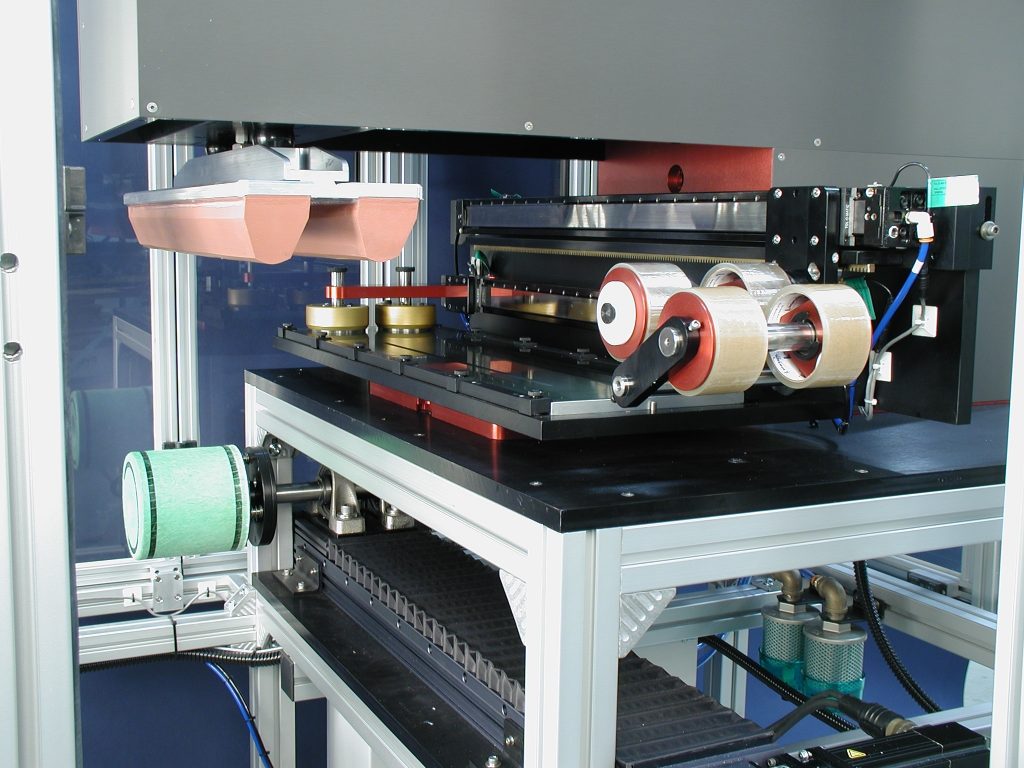

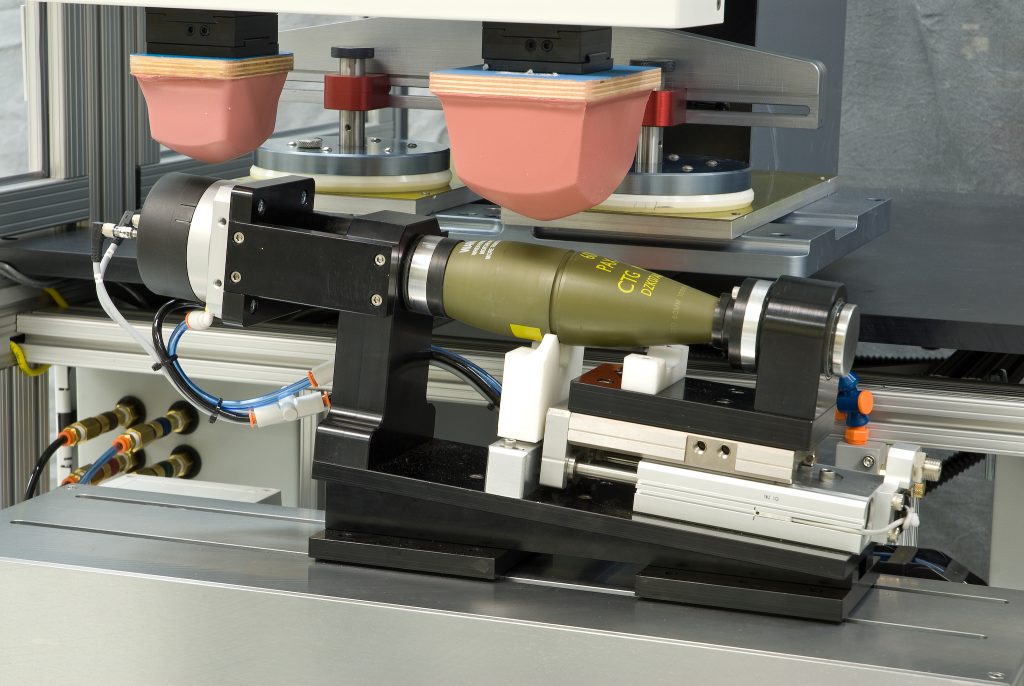

Medical Catheter, 360° Two color, Printing system

- (2) Color catheter printer with Tape cleaning device

- Revolutionary patented articulating printing head with single-angle silicone print pad to print 360° images

- Specialized catheter part-holding fixture tailored for artwork, equipped with a sensor-activated part-hold down feature

- Dual-color opposing transverse cup drive and plate system that efficiently delivers both colors in a single operation

Medical Catheter, 360° Two color, Printing system

- (2) Color catheter printer with Tape cleaning device

- Revolutionary patented articulating printing head with single-angle silicone print pad to print 360° images

- Specialized catheter part-holding fixture tailored for artwork, equipped with a sensor-activated part-hold down feature

- Dual-color opposing transverse cup drive and plate system that efficiently delivers both colors in a single operation

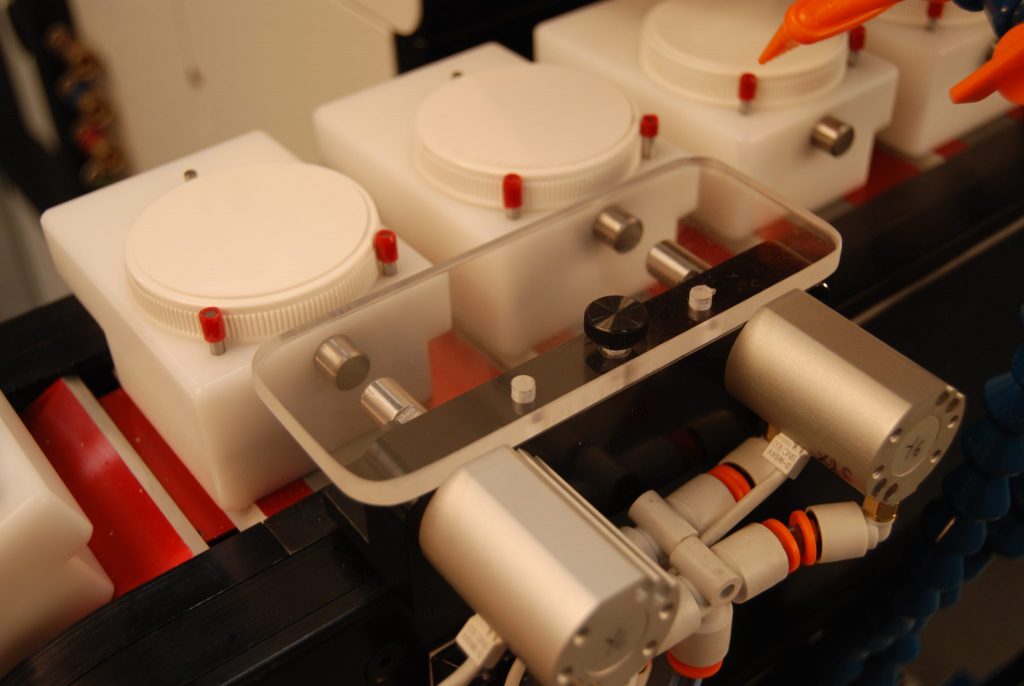

Medical Device 5 position 2-Up Printing System

- Printex model G8-150 DAW pad printer with automatic pad cleaning tape-off unit.

Independently actuated print heads - Mitsubishi PLC and HMI for seamless control and monitoring.

- 5 quick change, zero adjust Inking cup drive system

- 2-up Quick change, vacuum assist, zero adjust part holding fixtures secure components during processing.

- XYR-Adjustable work platform

- Guarding with interlocked safety switch doors and Keyence light curtains enhance operational safety.

Multi-Position Automotive Wiper Mode Selector

- (4) Zero adjust, 85mm printing plate system

- (4) Independently actuated printing heads

- (4) position Programmable Linear Servo Indexer

- A programmable rotational drive offers quick-change part holding fixtures, zero adjustment capabilities, simplifying fixture changes and guaranteeing precise printing positions without the need for adjustment.

- 100 Pre-programmed Job storage

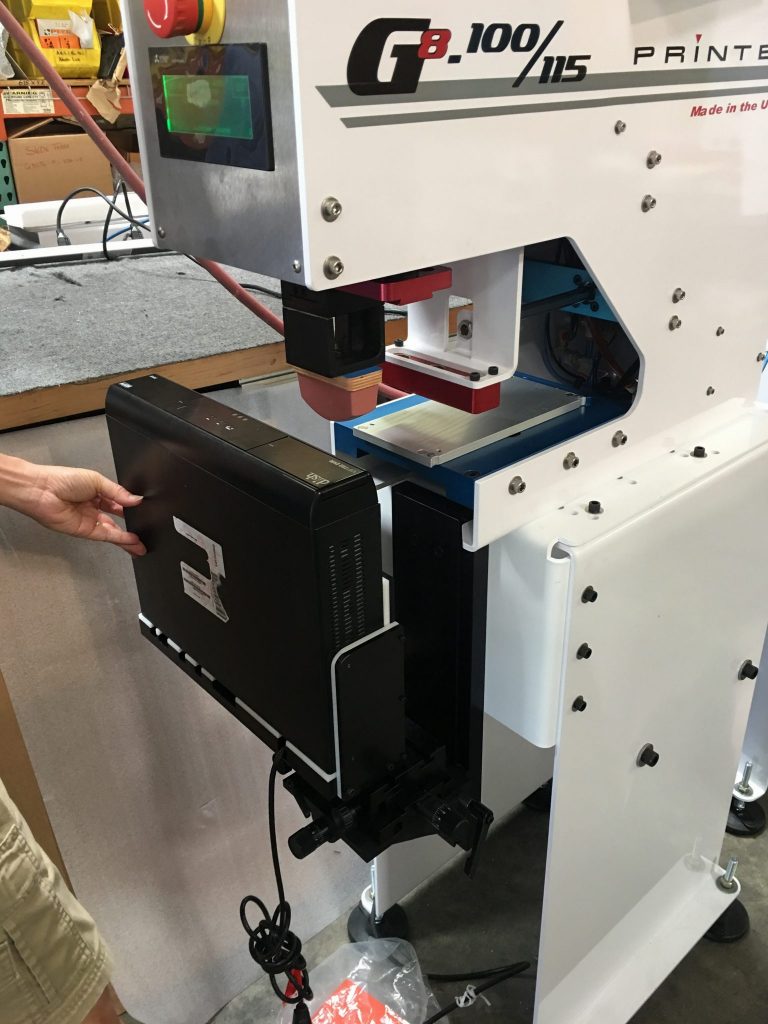

G8-100 Vape Cartridge 4-Up Printing System

- Printex model G8-100 Pad Printer

- Mitsubishi PLC and HMI for seamless control and monitoring.

- 4-up Quick change, part holding fixtures secure components during processing.

- Part present sensors detect the presence of parts at different stages.

- Quick change auto part loading magazine

- Post-print tack drying station ensures proper curing.

- 4-position automatic off-load track.

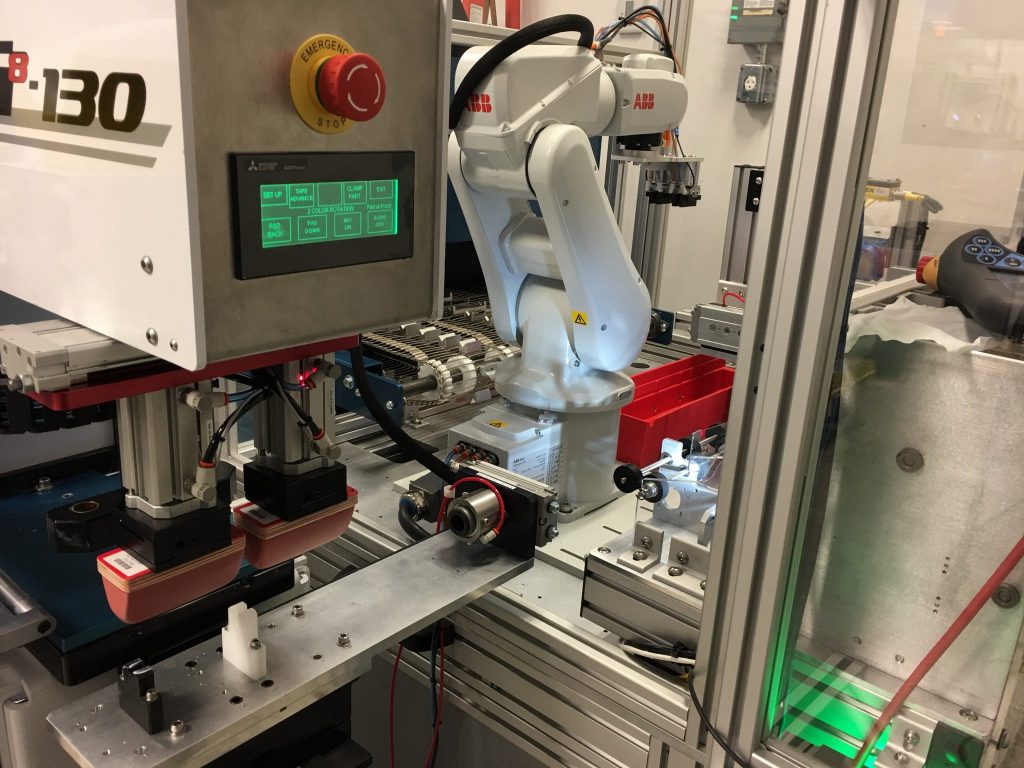

5-Color 200mm X-Y-Z Robotic Printer

Base Machine: G8-150 Double Action Wide

- (5) 200 mm wide artwork stations

- Programmable servo driven head movement (Y-Axis)

- Programmable servo driven part movement (X-Axis)

- (5) Independently actuated printing heads (Z-Axis)

- Combination of X-Y-Z positioning provides ultimate print position flexibility left/right, in/out, and print surface height.

- Tape Cleaning device

- Quick Change Fixtures

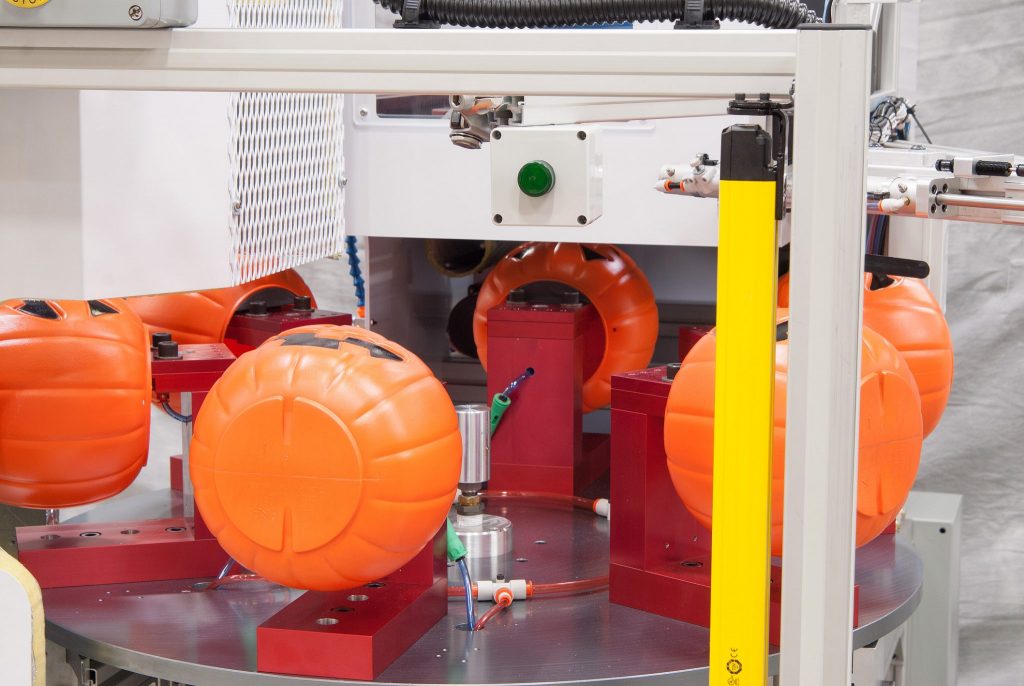

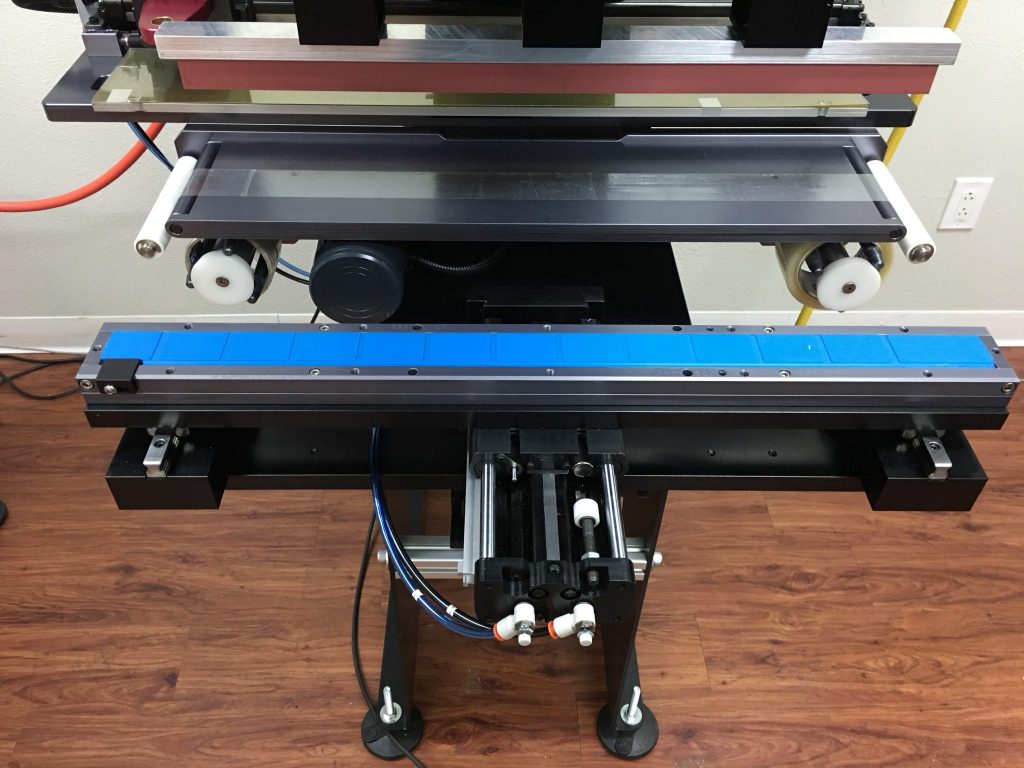

Multi-Color Turntable System With Automatic Unload

- (3) G8-100 Printers operating as slaves to the automation PLC

- (1) Horizontal printer to print on the side of the part

- (6) 100 mm wide artwork stations (3 machines printing 2-up)

- Part present sensors

- Perimeter light curtain guarding

- Warm air dry station

- Automatic part unload